Frequently asked questions.

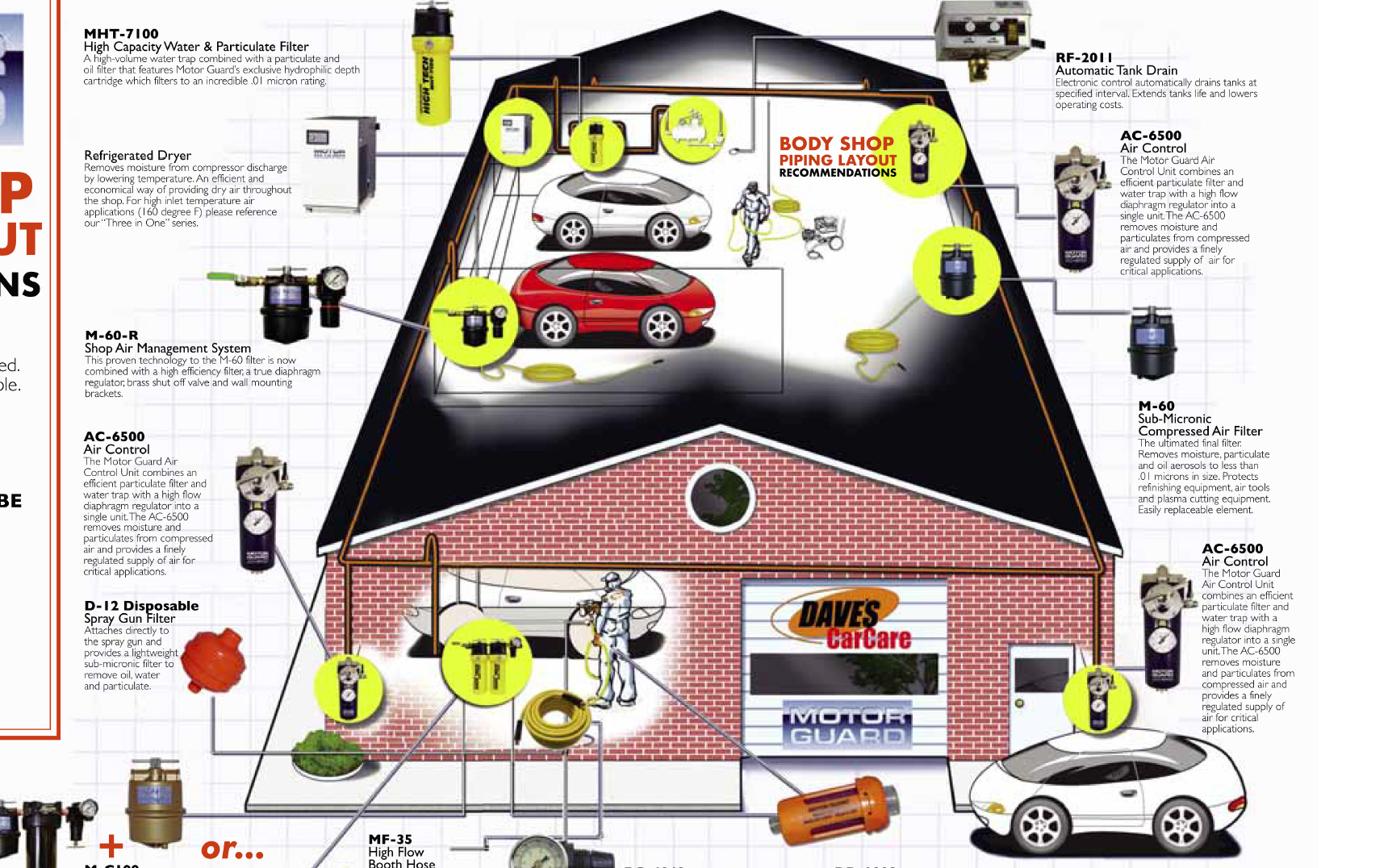

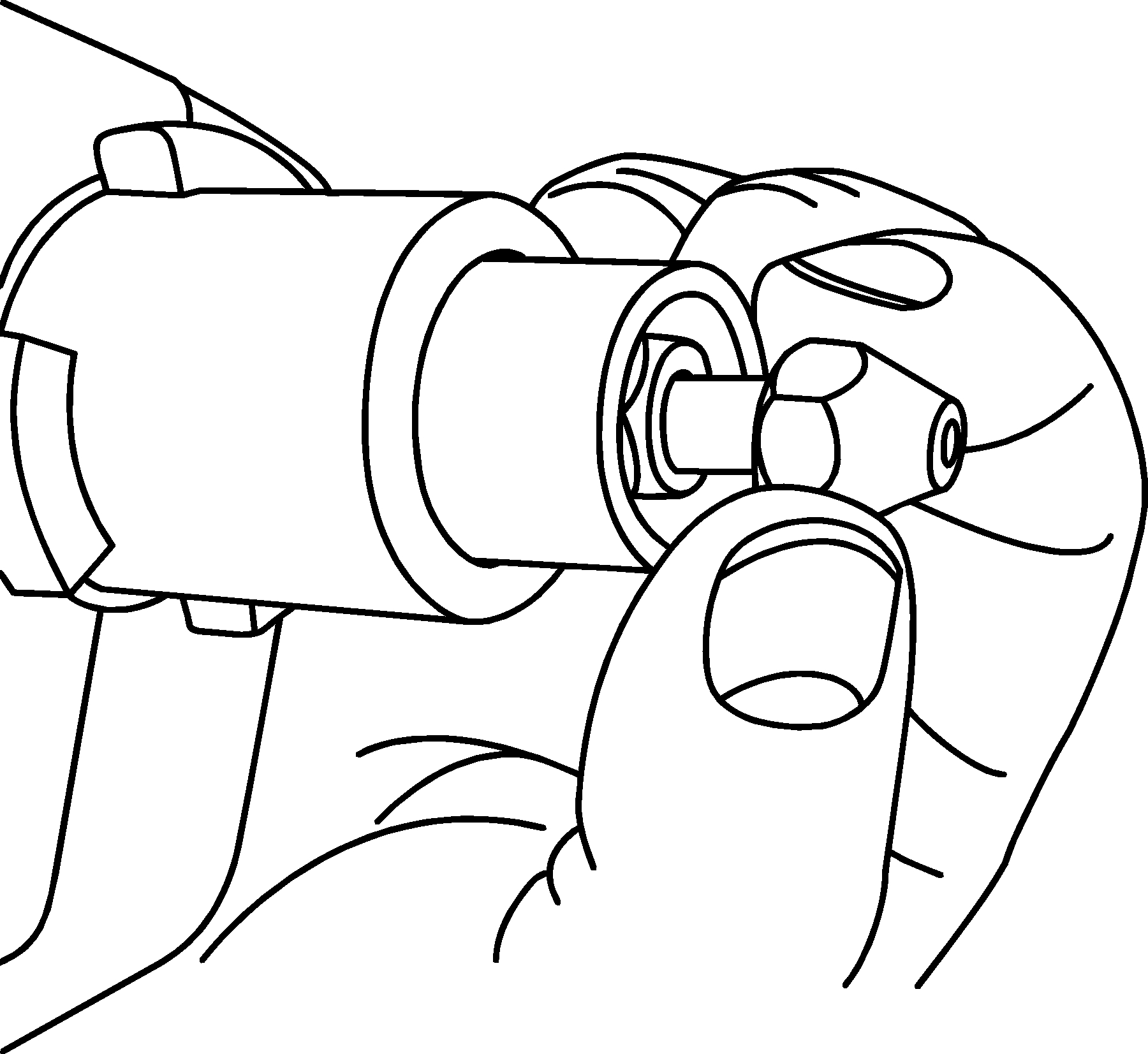

See the figures below. First, install the stud electrode tip, tapered end first, and rotate slightly for a tight fit. Next, insert a welding pin into the electrode, pushing firmly to seat the electrode in the Manga Pin System (MPS) holder. The MPS holder will prevent the pin from falling out in any welding position. See instruction manual for more information.

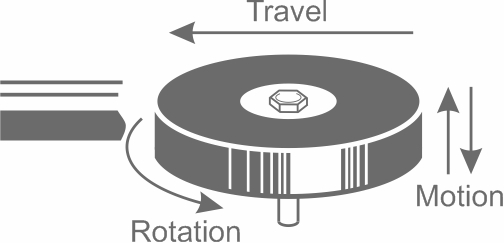

Before using tool on a critical area, pick an area to test operation. Start tool and bring wheel in contact with work surface. With wheel rotation shown, start at right side of adhesive and work to the left, applying light pressure. A slight up and down motion will speed removal. For maximum wheel life, a speed of 1500 RPM is recommended. Optimal speed will vary with thickness of adhesive residue, with heavier residue requiring a lower speed. As a rule of thumb, the higher the speed, the lighter the pressure required. With proper operation, wheel will not harm clear coat and no cleanup is required. Replace wheel when outer diameter approaches 2″, thus preventing accidental contact with metal washer.

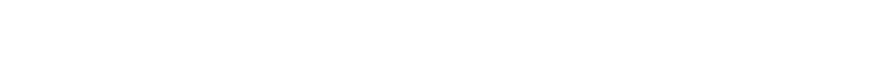

Mount filter as close to possible to point of use. Allow at least 20 feet of piping between air compressor outlet and filter as this will allow discharge air to cool sufficiently for proper filter operation.

Install appropriate fittings needed to adapt filter to in-place piping. A ball-type or other positive shutoff valve or disconnect should be installed upstream of the filter to isolate filter for maintenance. Apply pipe thread compound to male threads only. Do not over tighten fittings.

Note direction of airflow before installing filter; “IN” – connection to compressed air supply, ”OUT” – connection to tool or equipment.

Filter should be replaced before the element has become saturated and will no longer trap water. The following general guidelines may be used for the replacement interval:

- Heavy use on dirty air systems – Daily

- Moderate use on average air systems – Weekly

- Intermittent use on clean air systems – Monthly